Services Performed

- Remove all necessary accessories and door panel fasteners in order to remove the door panel to access the power window components. Drill the rivets or unbolt regulator assembly and discard. Clean and tighten all terminal connections to ensure proper mating between the replacement motor and connector. Apply di-electric grease to the connections to prevent moisture build up and position the new regulator and motor assembly into the door. Fasten the regulator to the door frame and check for proper alignment. Lubricate the internal door components (linkages, actuators, and window tracks), and reinstall all components back to original configuration setting travel limits, and clearance the internal harnesses. Test to verify proper operation of the window, and all door related functions to confirm repairs.

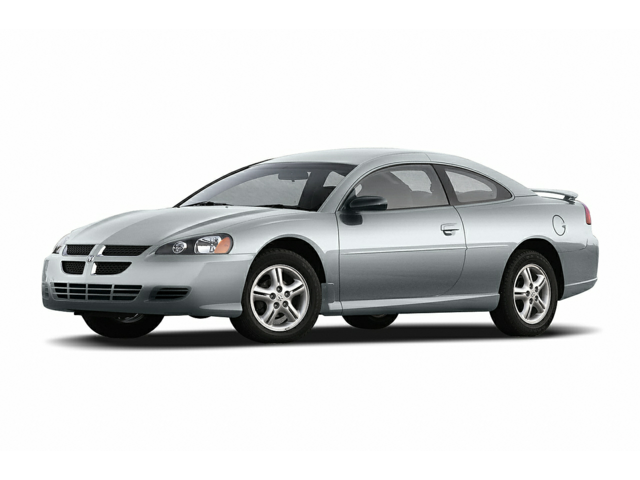

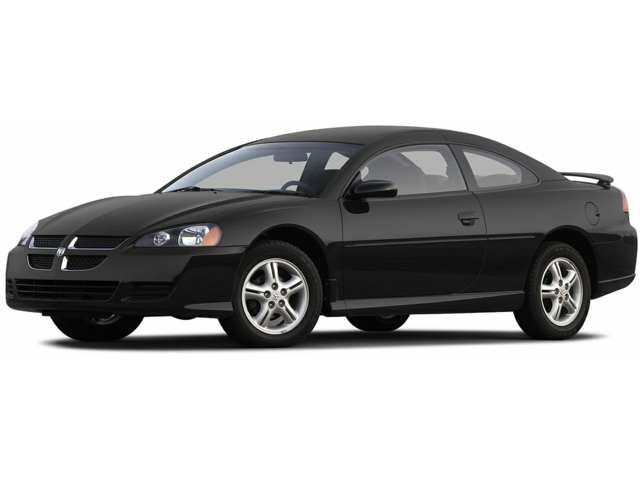

Stanton B. gave our service a 5 star review on 8/19/2022